The rise of e-cigarettes in recent years has sparked curiosity among both smokers looking for alternatives and individuals interested in how these devices are engineered. Understanding how e-cigarettes are made is crucial not only for users but also for those in the industry. These devices, designed to simulate traditional smoking, offer a glimpse into modern electronic innovation and precision manufacturing.

Raw Materials and Initial Steps

E-cigarettes start with a variety of raw materials. At the core are the batteries, usually lithium-ion, known for their long-lasting power. These components are fundamental, providing the necessary energy for the e-cigarette to function effectively. Another key component is the atomizer, which consists of wiring and a metallic coil. These need to be carefully selected and tested for reliability and safety.

The assembly begins with molding the exterior casing, commonly made from durable plastics or metals like stainless steel. This casing not only houses the electronic components but also provides a sleek, ergonomic design preferred by consumers. During the initial production phase, the precision of machinery ensures that all parts are fitted with exactness, critical for device safety and functionality.

Manufacturing the Atomizer

The atomizer unit

is a core part of how an e-cigarette operates. It is responsible for heating the liquid and turning it into a vapor. The manufacturing process involves winding a coil from a resistant wire, usually made from stainless steel or kanthal. This wire is then wrapped around a wick typically made from cotton to ensure optimal liquid absorption and efficient vapor production.

is a core part of how an e-cigarette operates. It is responsible for heating the liquid and turning it into a vapor. The manufacturing process involves winding a coil from a resistant wire, usually made from stainless steel or kanthal. This wire is then wrapped around a wick typically made from cotton to ensure optimal liquid absorption and efficient vapor production.

The coil and wick are carefully assembled to avoid short circuits and enhance vapor quality. These components must undergo rigorous testing, ensuring that each part meets safety standards before being integrated into an e-cigarette.

Flavors and E-liquids

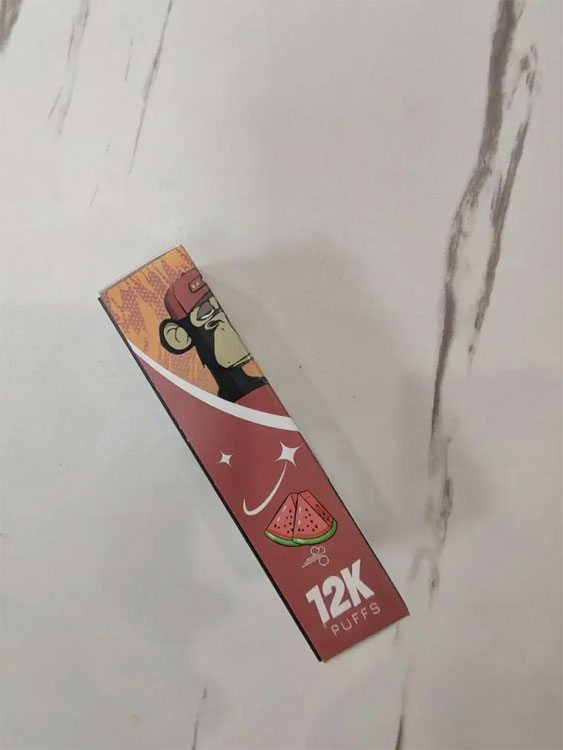

The heart of an e-cigarette’s appeal lies in its e-liquid. Generally consisting of propylene glycol (PG) and vegetable glycerin (VG) bases, along with nicotine and flavorings, these mixtures are meticulously crafted. Each ingredient is measured with precision and mixed to produce numerous flavors that cater to a wide range of tastes, from traditional tobacco to exotic fruits.

The e-liquid production process demands stringent quality control. Manufacturers must ensure the consistency and purity of the liquids to maintain safety standards and customer satisfaction. The goal is to deliver a smooth and enjoyable experience to the user while abiding by health regulations.

Assembly and Quality Checks

Once individual components such as the battery, atomizer, and casing are prepared, the assembly process begins. Automation plays a significant role in aligning these parts correctly. The electronic circuit that allows the user to activate the device, manage power settings, and monitor usage is installed with precision.

Quality assurance is paramount during this stage. Manufacturers conduct a series of tests on each device to check its operational status, verifying safety features and overall performance. These tests are designed to catch defects before the products are packaged and distributed to the market.

Adhering to Regulations

Manufacturers must remain compliant with regulations that govern the production of e-cigarettes. These regulations vary by region but generally focus on safety, emission levels, and labeling standards. Strict adherence to these rules is essential to avoid legal issues and ensure consumer trust.

Packaging and Distribution

Once all checks are passed, the final stage in how e-cigarettes are made involves packaging and distribution. The packaging must be secure to protect delicate components and often includes instructions for use and safety information. Distribution networks must then ensure that the products reach retailers in good condition, maintaining the integrity of the devices until they reach consumers.

Conclusion

Understanding the intricate engineering behind e-cigarettes deepens appreciation for these devices. Their production is a testament to precision and innovation, combining electronics with user-centric design and safety. As technology advances, we can anticipate further enhancements in how these fascinating devices are made and used.

FAQs

Q: Are the materials used in e-cigarettes safe?

A: Manufacturers use materials that are tested for safety and compliance with industry standards. The batteries, circuits, and e-liquids are crafted to meet strict regulations to ensure consumer protection.

Q: How long does the production process take?

A: The production timeline varies depending on the scale and technological complexity but generally takes a few weeks from sourcing raw materials to the final product.

Q: Can e-cigarettes be recycled?

A: Components like batteries and certain plastics can be recycled. Consumers should check with local guidelines for e-waste disposal to ensure proper recycling.